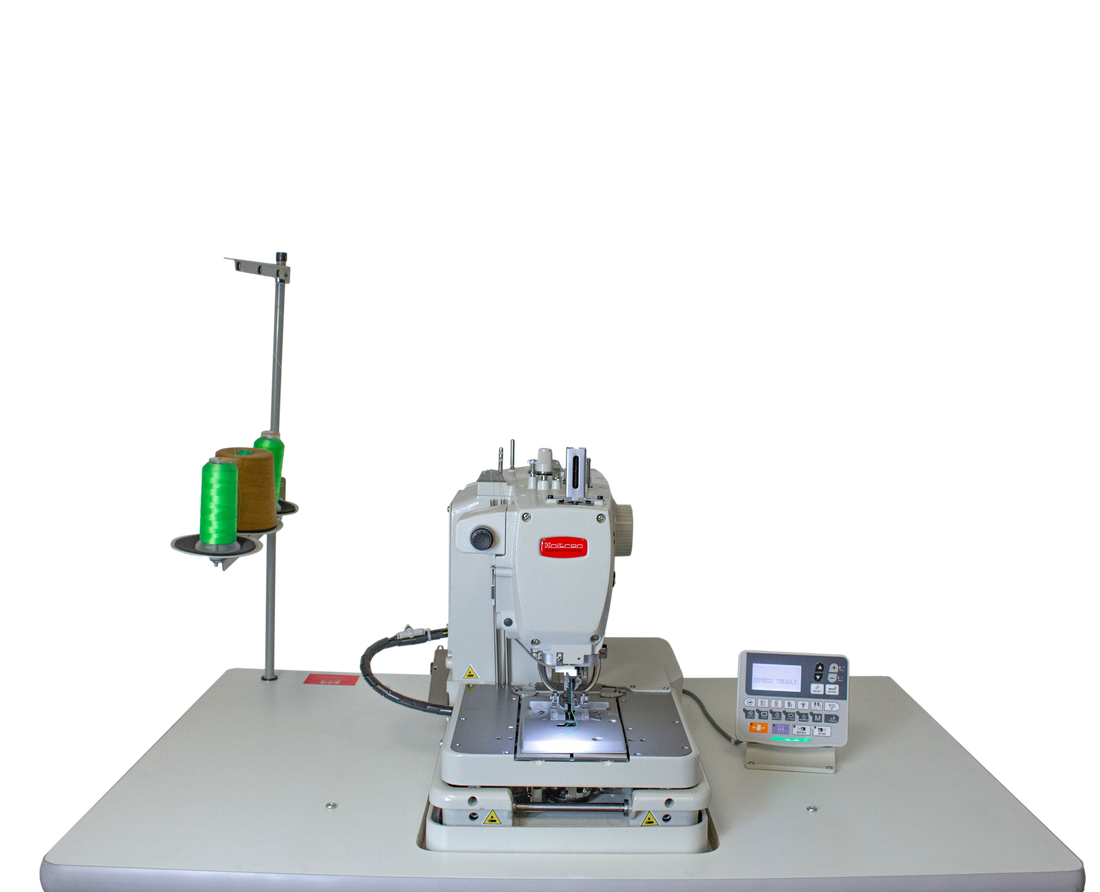

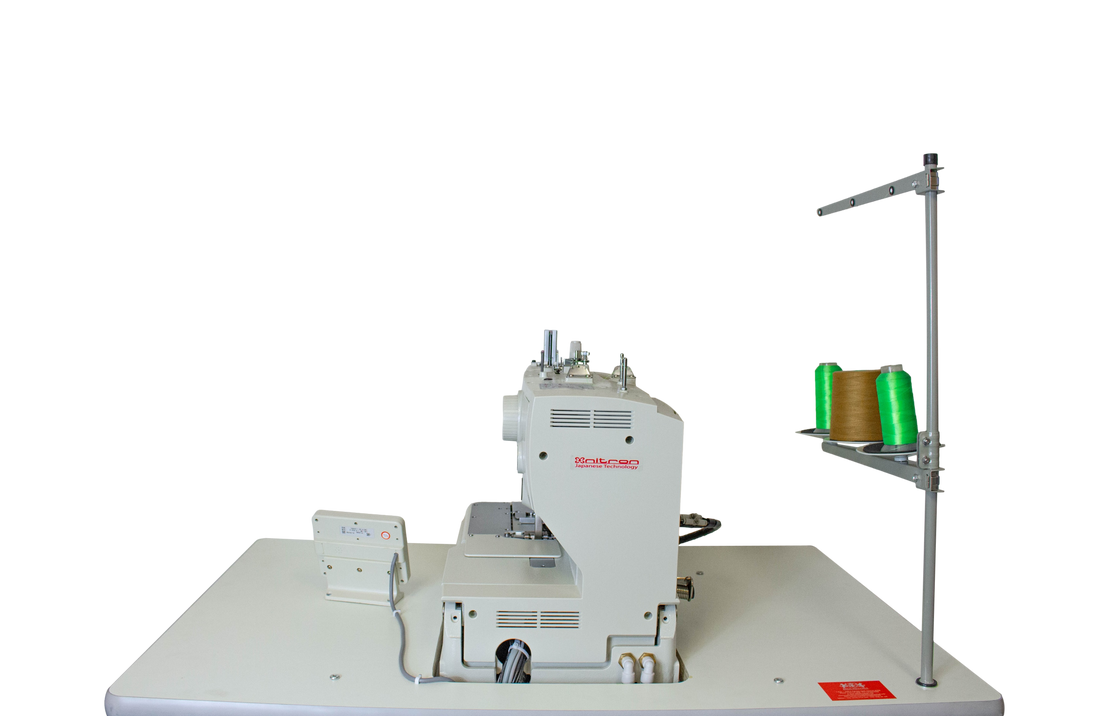

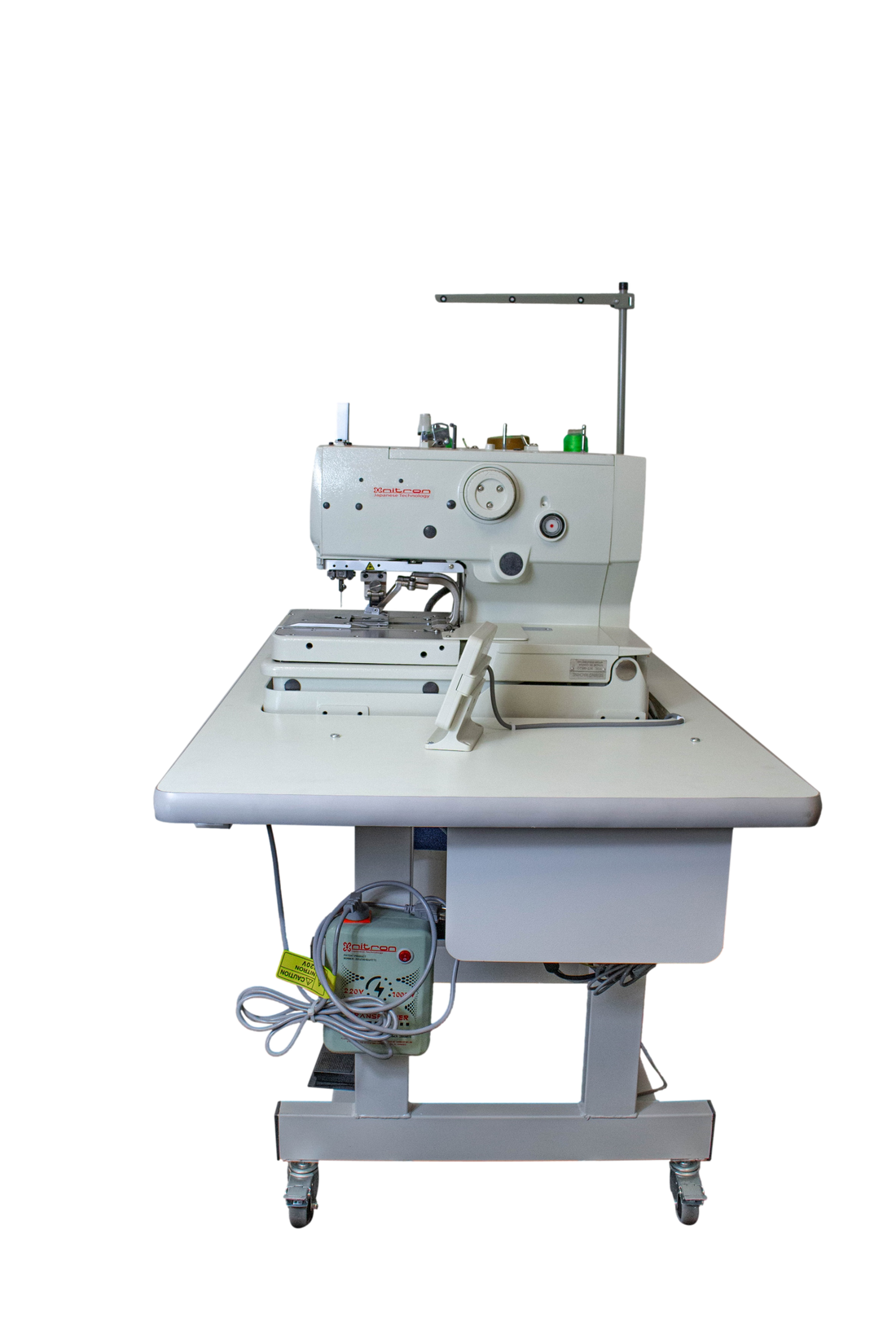

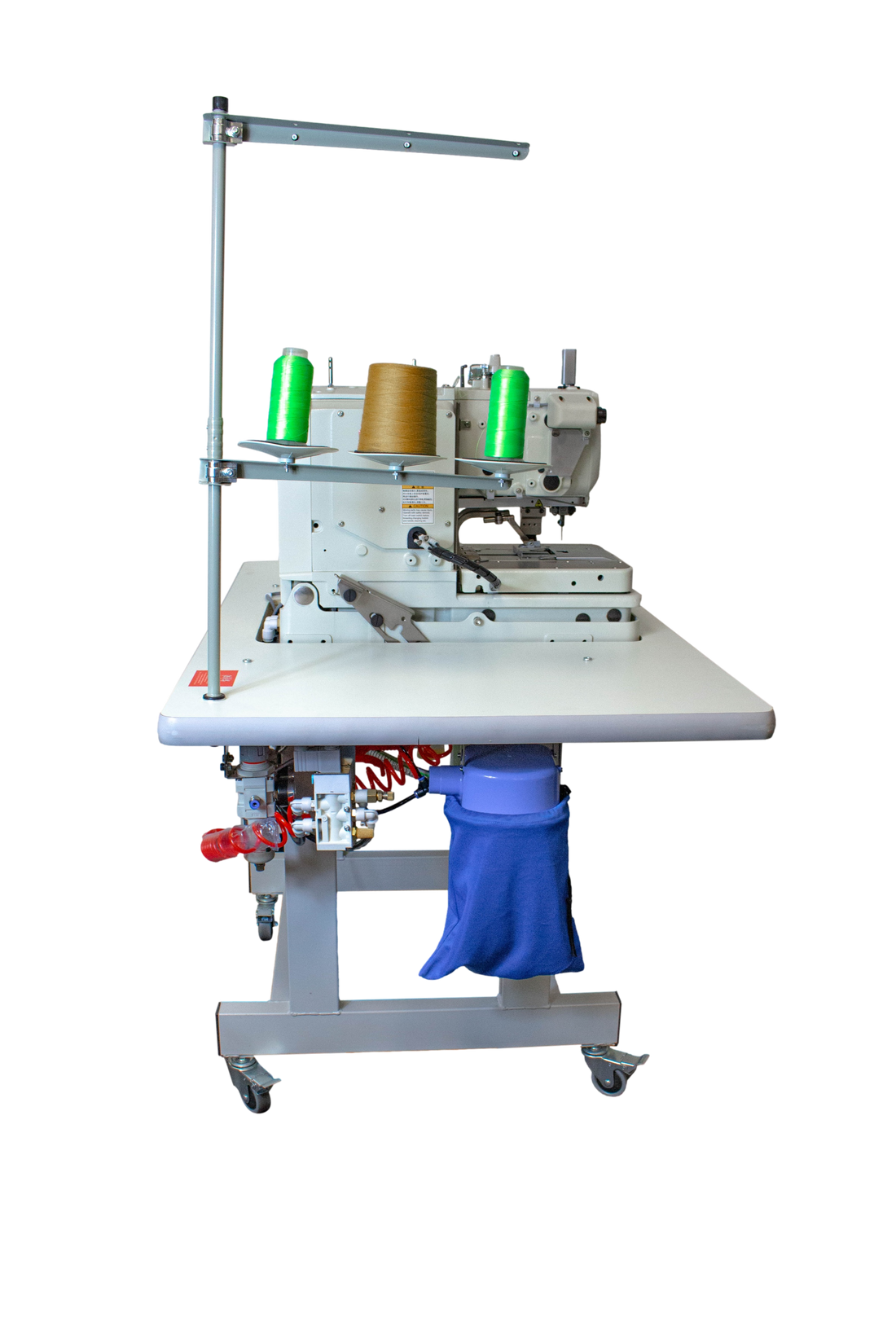

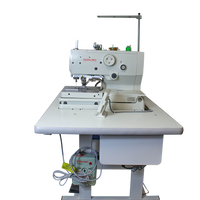

NT-9820-01 MÁQUINA DE COSER DE OJO DE LLAVE

$7,300.00

- Descripción

Special Features:

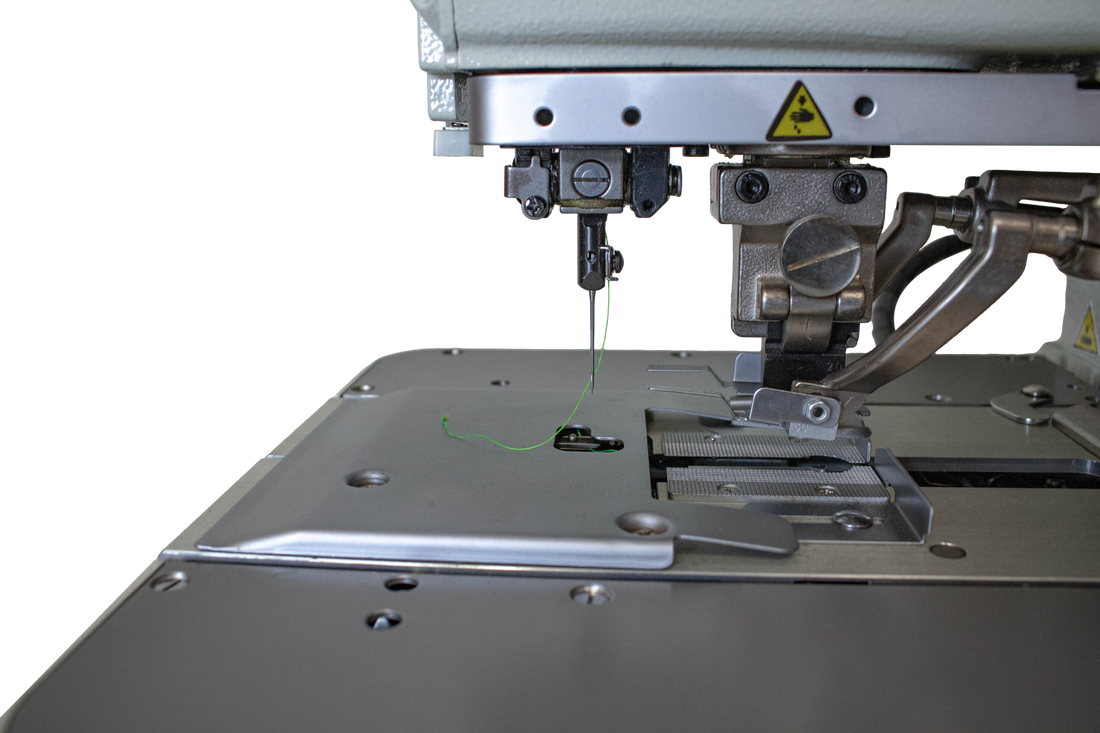

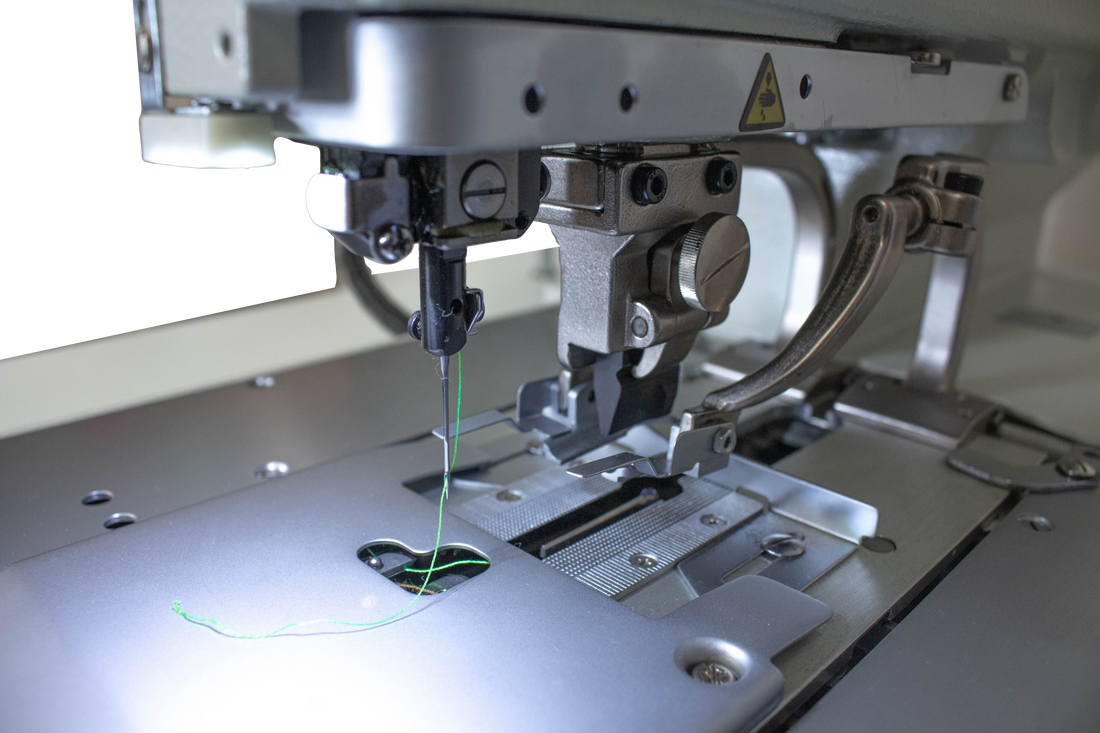

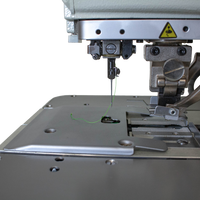

• Precision of stitch point has been improved. With the highly-rigid feed mechanism with servo control, stitch point is very precise and feed drifting, which is specific to electronic sewing machines, does not occur even in high-speed sewing of weighty materials. The servo control also makes home position detection unnecessary.

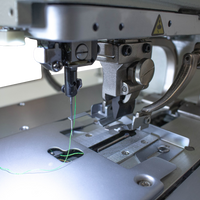

• Skipped stitches are reduced. The shape of the looper, the thread take-up amount and some other parts have been reviewed. Skipped stitches and insufficient thread tightening due to a change of thread tension are reduced, regardless of types of threads. The range of sewing capability has been enlarged.

• Large arm pocket providing ease of operation. The arm pocket of 120mm depth gives a sufficient shape, enabling material setting smooth. It is the view of the needle area, allowing operators to observe the sewing operation.

• Sewing with less noise. With thorough review of the mechanisms causing noise, quieter sewing even at higher sewing speed than the conventional model has been realized. The machine is made with a sound design gentle to ears, eliminating impact noise. The vibration of the feed base which is transmitted to an operator is also reduced. The corking environment with less operator fatigue can be materialized.

• Operation panel easy to use for everyone. Nitron NT-9820 is equipped with a liquid crystal display (LCD) and indicates display items with icons and letters. Setting and check of sewing patters and change of sewing modes are easy to understand and carry out.

• Easy maintenance. Daily cleaning and lubrication can efficiently be done in a shorter time due to Centralized Lubrication System. Thread waste can be collected and Eyelet cloth chips can be cleared.

Specifications:

SEWING SPEED: 1,000 – 2,500 RPM (Setting possible in units of 100 RPM)

SEWING SHAPE: Without Bartack, Taper Bartack, Straight Bartack, Round Bartack and Circular Stitch.

SEWING LENGTH: 5-50mm

STITCH PITCH: 0.50 – 2.0mm

ZIGZAG WIDTH: 1.5 – 5.0mm (Max 4.0 mm with mechanism, Max. 1.0mm with software)

TAPER BARTACK LENGTH: 0-20mm

WORK CLAMP HEIGHT: Standard 12mm (up to 16mm possible)

STARTING METHOD: Foot switch (treadle type, 2-pedal type) or hand start switch.

FEED MECHANISM: Intermittent feed by three pulse motors

NEEDLE: DO x 558 80-120 Nm (Schmetz 558)

SAFETY DEVICES: Built in emergency stop function and automatic stopping device which stops the machine when the safety circuit is activated.

UPPER SHAFT MOTOR: AC servo motor (4-pole, 550 W)

AIR PRESSURE: Main regulator: 0.5MPa, Hammer pressure regulator: 0.4 MPa

AIR CONSUMPTION: 43.2 l/min (8 cycles/min)

POWER SUPPLY: Single-phase 100V/220V, Three-phase 200V/220V/380V/400V 400VA

WEIGHT: Machine head: Approx. 120kg (265Lbs)

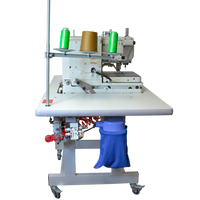

Application: Ideal for Men's suits and Jeans , workwear

• Precision of stitch point has been improved. With the highly-rigid feed mechanism with servo control, stitch point is very precise and feed drifting, which is specific to electronic sewing machines, does not occur even in high-speed sewing of weighty materials. The servo control also makes home position detection unnecessary.

• Skipped stitches are reduced. The shape of the looper, the thread take-up amount and some other parts have been reviewed. Skipped stitches and insufficient thread tightening due to a change of thread tension are reduced, regardless of types of threads. The range of sewing capability has been enlarged.

• Large arm pocket providing ease of operation. The arm pocket of 120mm depth gives a sufficient shape, enabling material setting smooth. It is the view of the needle area, allowing operators to observe the sewing operation.

• Sewing with less noise. With thorough review of the mechanisms causing noise, quieter sewing even at higher sewing speed than the conventional model has been realized. The machine is made with a sound design gentle to ears, eliminating impact noise. The vibration of the feed base which is transmitted to an operator is also reduced. The corking environment with less operator fatigue can be materialized.

• Operation panel easy to use for everyone. Nitron NT-9820 is equipped with a liquid crystal display (LCD) and indicates display items with icons and letters. Setting and check of sewing patters and change of sewing modes are easy to understand and carry out.

• Easy maintenance. Daily cleaning and lubrication can efficiently be done in a shorter time due to Centralized Lubrication System. Thread waste can be collected and Eyelet cloth chips can be cleared.

Specifications:

SEWING SPEED: 1,000 – 2,500 RPM (Setting possible in units of 100 RPM)

SEWING SHAPE: Without Bartack, Taper Bartack, Straight Bartack, Round Bartack and Circular Stitch.

SEWING LENGTH: 5-50mm

STITCH PITCH: 0.50 – 2.0mm

ZIGZAG WIDTH: 1.5 – 5.0mm (Max 4.0 mm with mechanism, Max. 1.0mm with software)

TAPER BARTACK LENGTH: 0-20mm

WORK CLAMP HEIGHT: Standard 12mm (up to 16mm possible)

STARTING METHOD: Foot switch (treadle type, 2-pedal type) or hand start switch.

FEED MECHANISM: Intermittent feed by three pulse motors

NEEDLE: DO x 558 80-120 Nm (Schmetz 558)

SAFETY DEVICES: Built in emergency stop function and automatic stopping device which stops the machine when the safety circuit is activated.

UPPER SHAFT MOTOR: AC servo motor (4-pole, 550 W)

AIR PRESSURE: Main regulator: 0.5MPa, Hammer pressure regulator: 0.4 MPa

AIR CONSUMPTION: 43.2 l/min (8 cycles/min)

POWER SUPPLY: Single-phase 100V/220V, Three-phase 200V/220V/380V/400V 400VA

WEIGHT: Machine head: Approx. 120kg (265Lbs)

Application: Ideal for Men's suits and Jeans , workwear