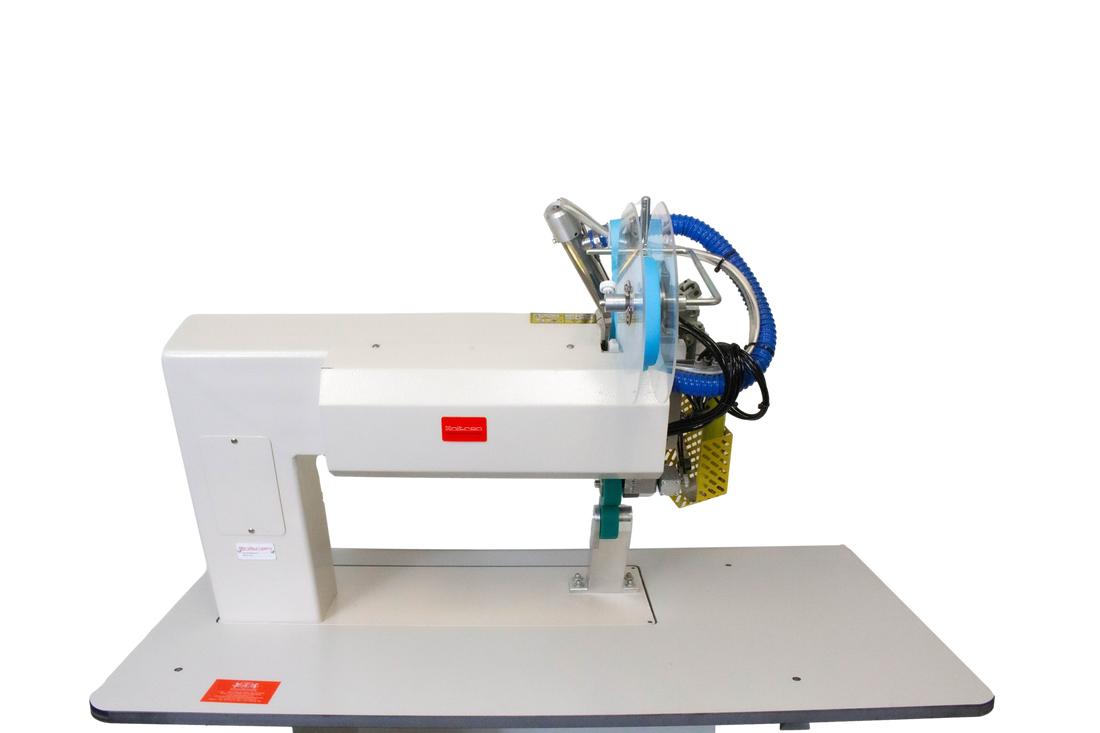

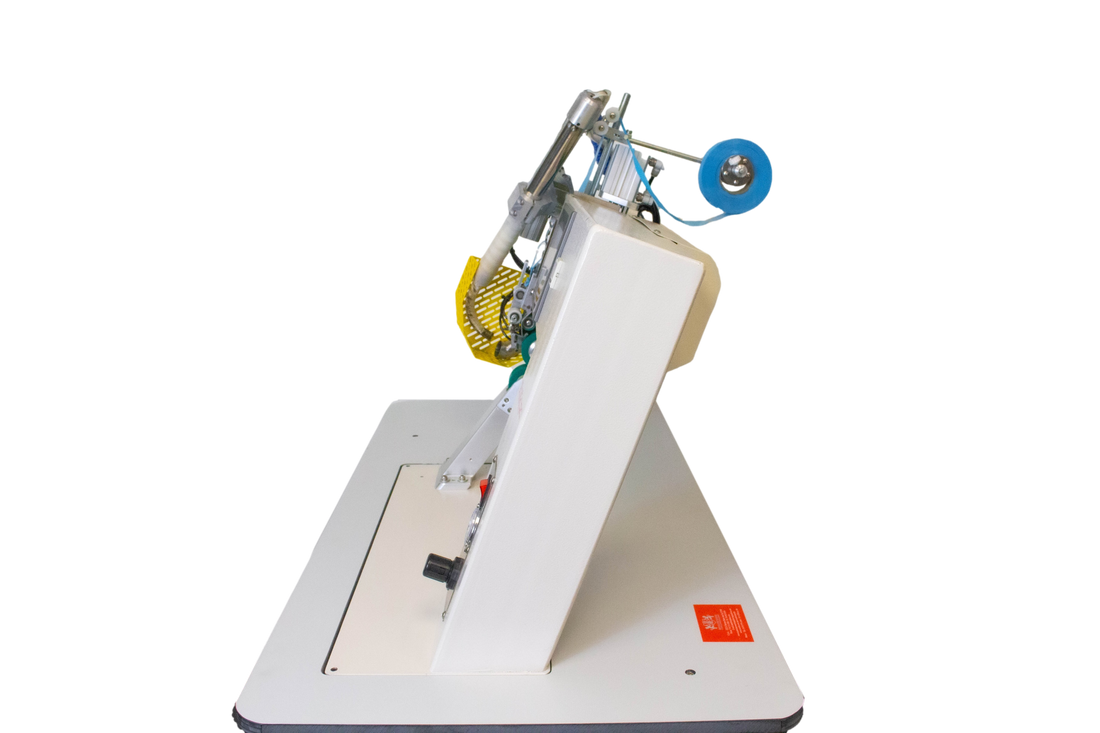

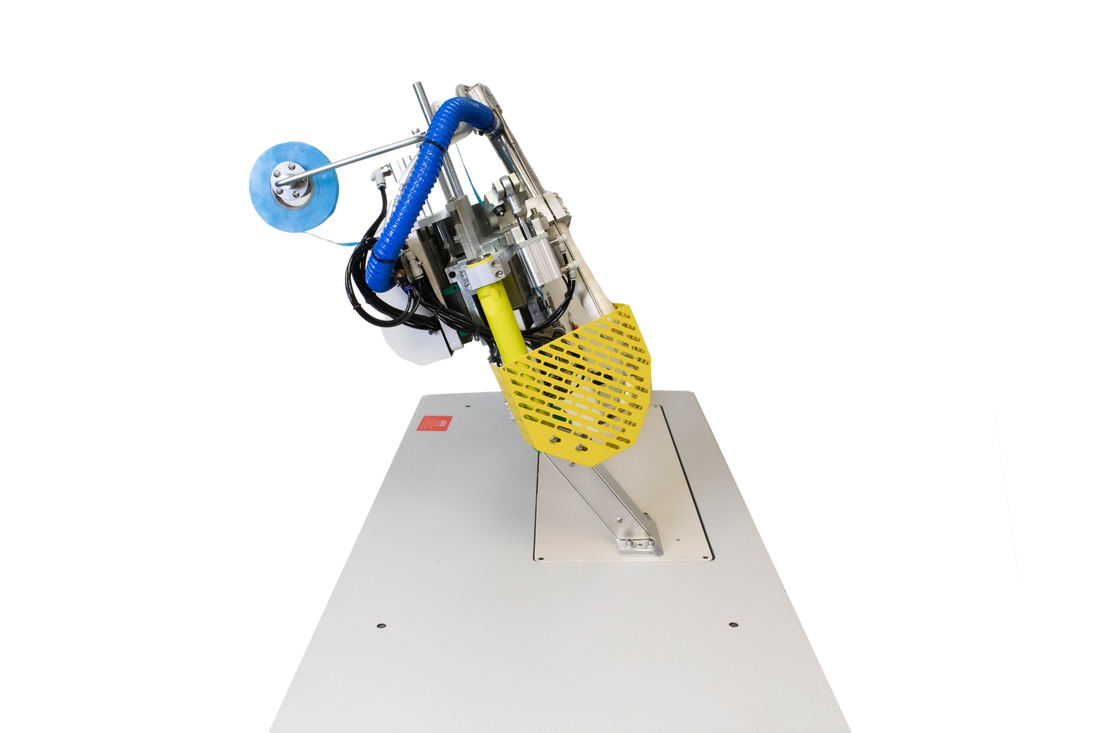

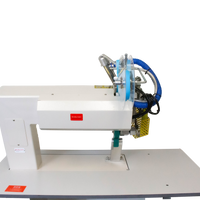

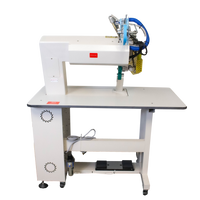

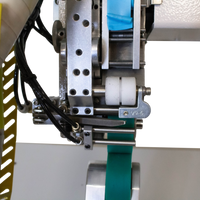

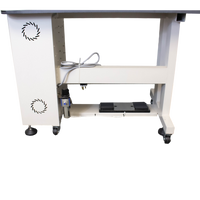

NT-2020-V9 HOT TAPE SEALING MACHINE

$5,850.00

- Description

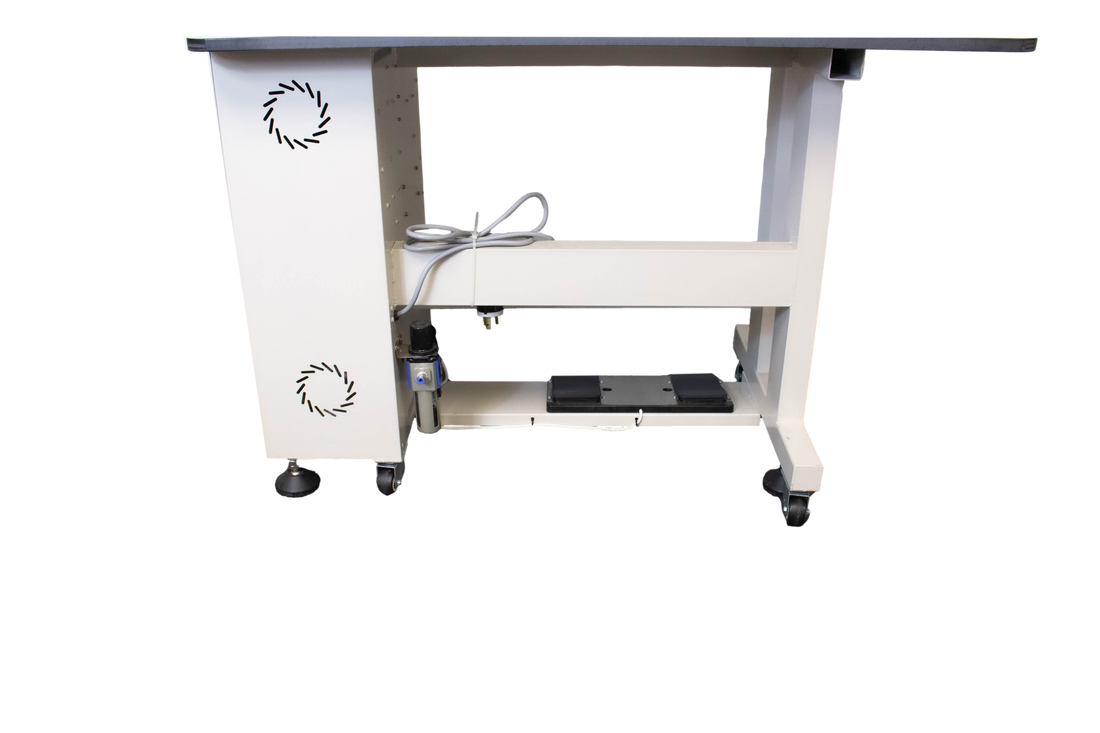

General Description:

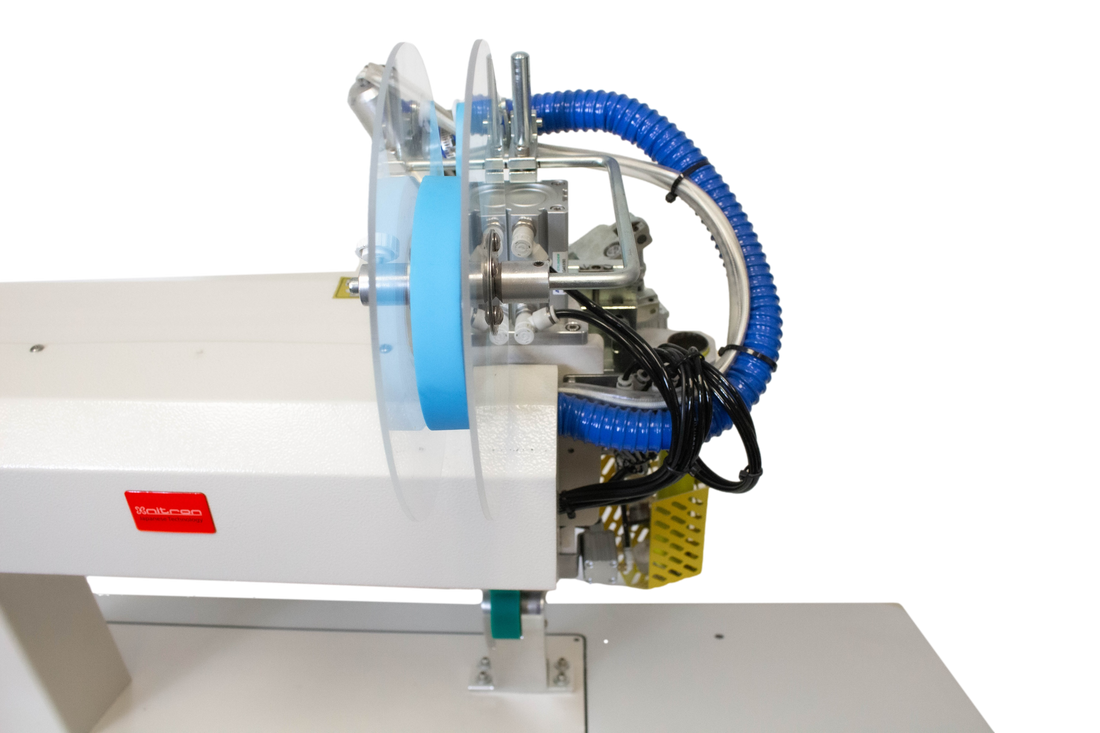

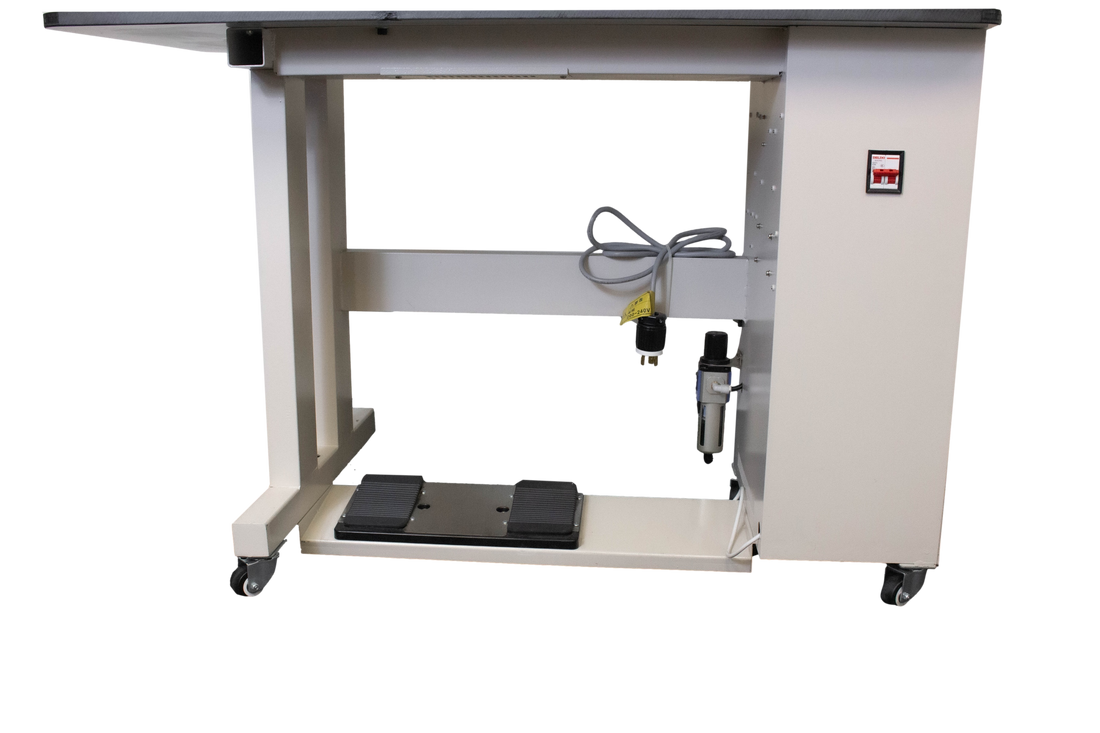

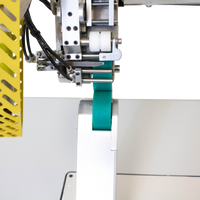

NT-2020-V-9 Hot tape sealing machine was developed for welding continuous seams on water-resistant, waterproof, and breathable materials. It can also be used for cross seams with 3 material plies.

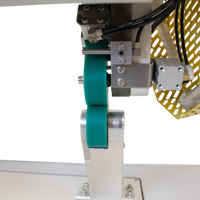

- Traditional tape welding combined with the possibility of programmed welding

- Maximum reproducibility of the welding process

- 20% increased productivity in comparison to other tape welding machines

- Up to 15% reduction of the amount of tape used compared to standard machines

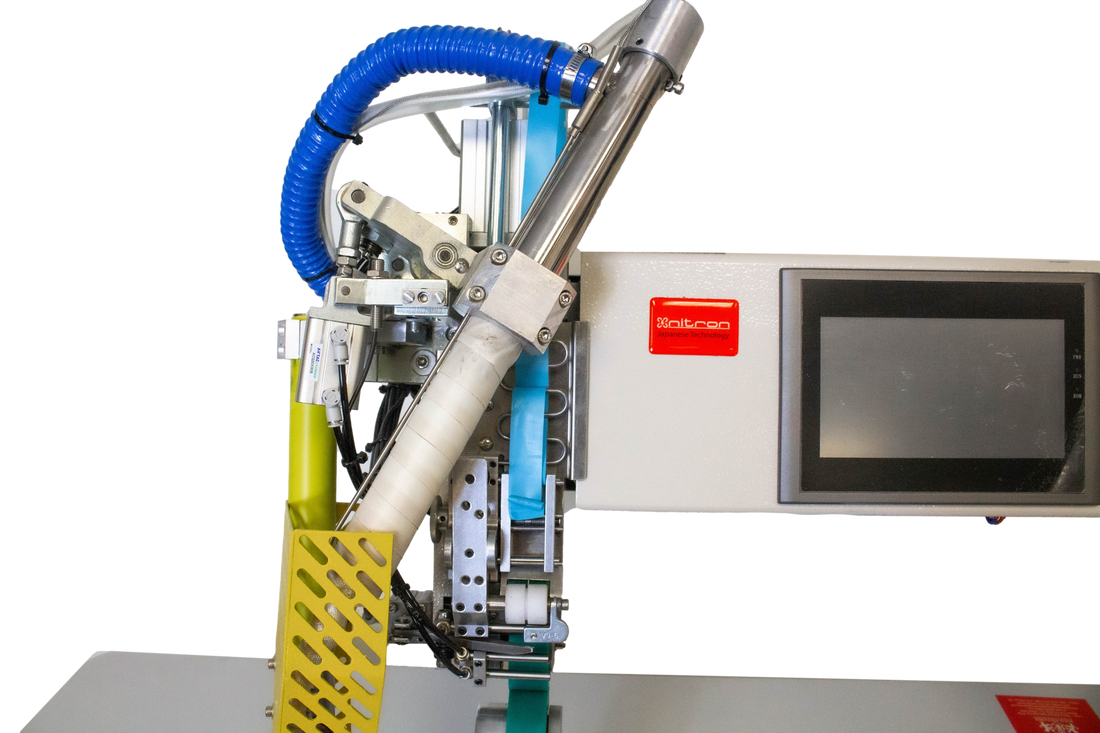

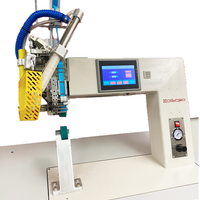

- Touch screen for easy operation with pictograms

- Various operator levels are possible, with password protection, e.g. fixed parameters cannot be altered by the operator

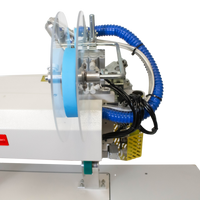

- Monitoring of the heating temperature with two sensors (optional)

- Individual segments, as well as complete sequences, can be programmed

- Automatic monitoring and maintaining of all pre-set or programmed parameters

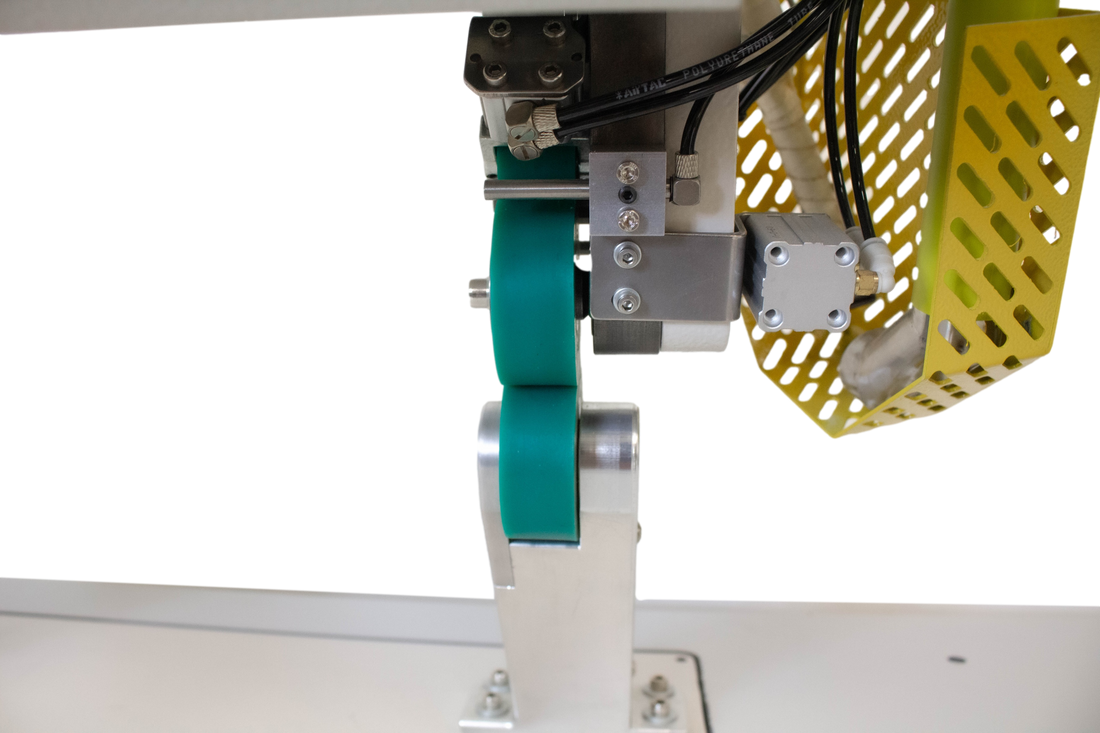

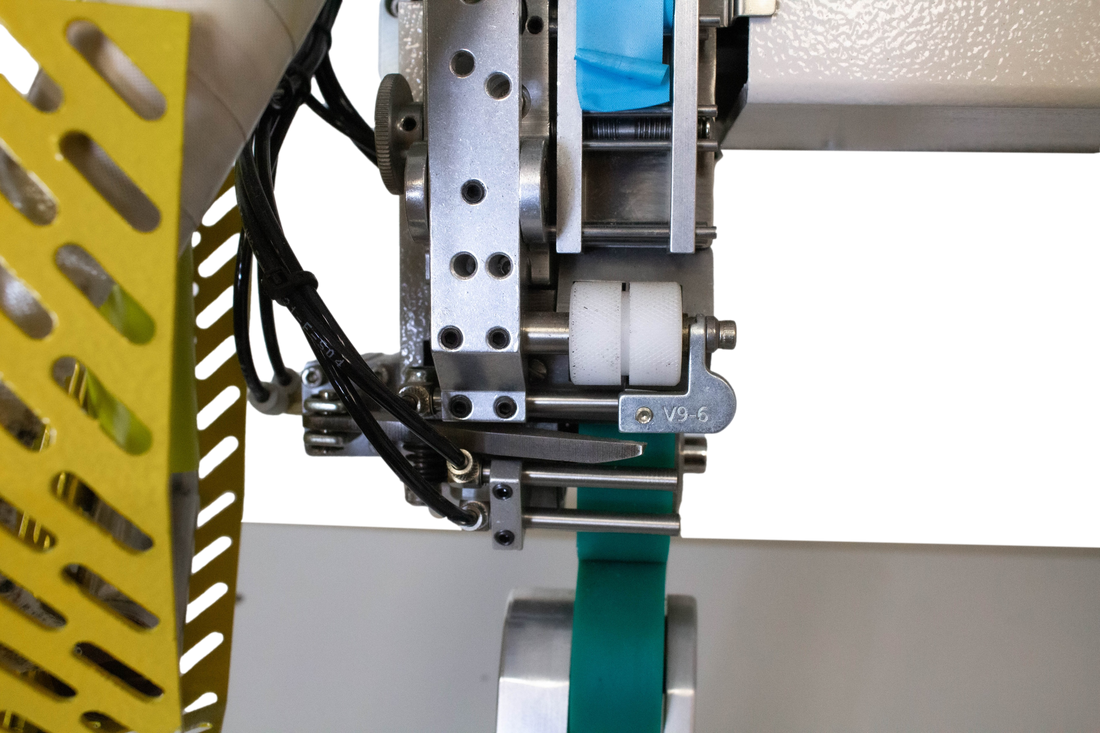

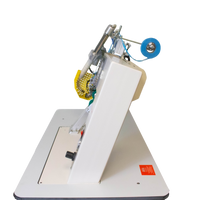

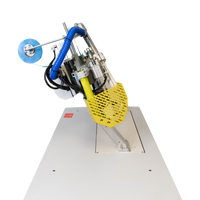

- Variable post system (post width and position – depending on use)

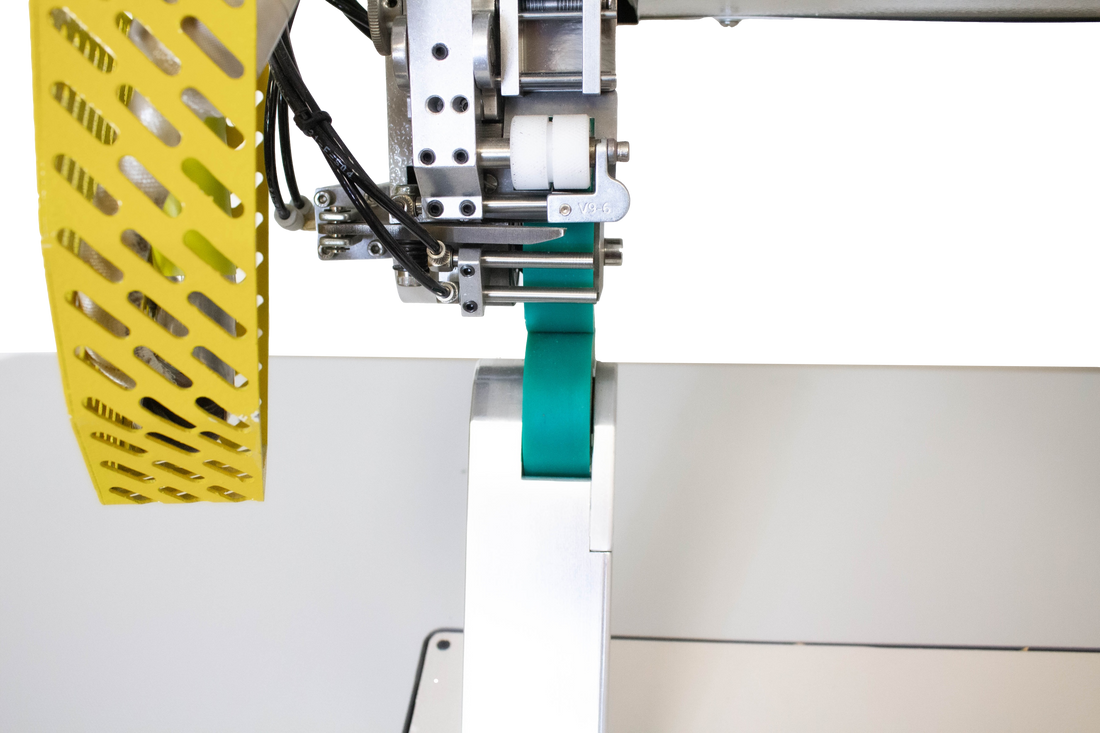

- Exactly reproducible nozzle setting with x/y-carriages