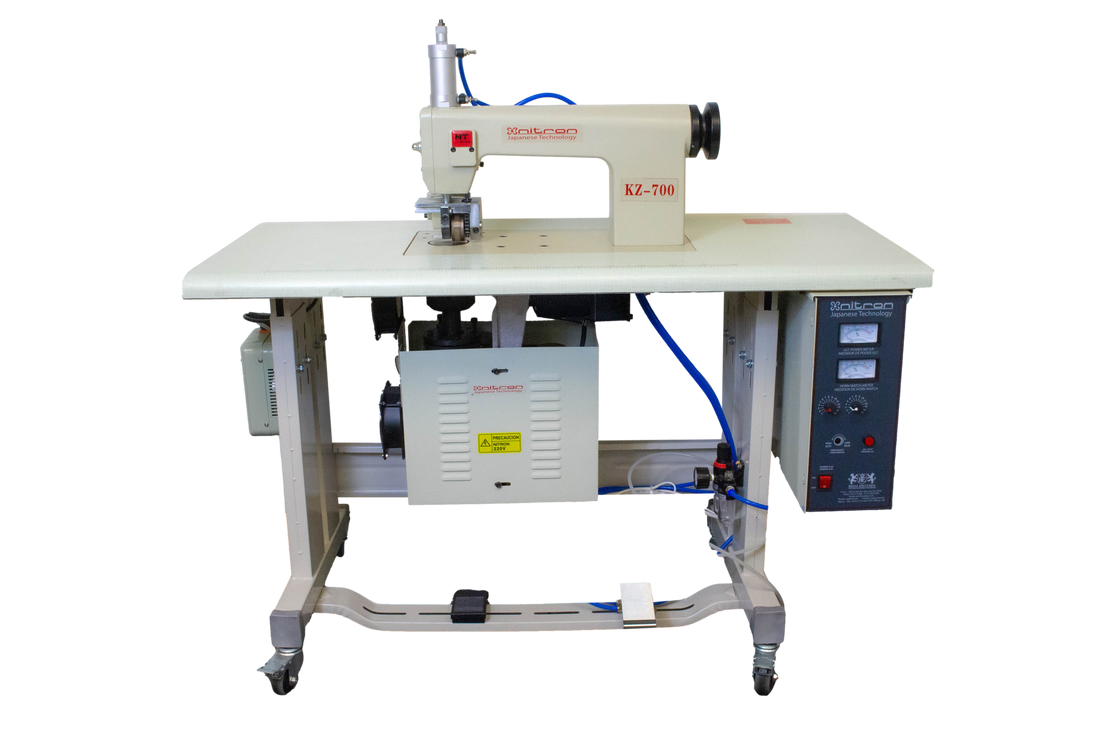

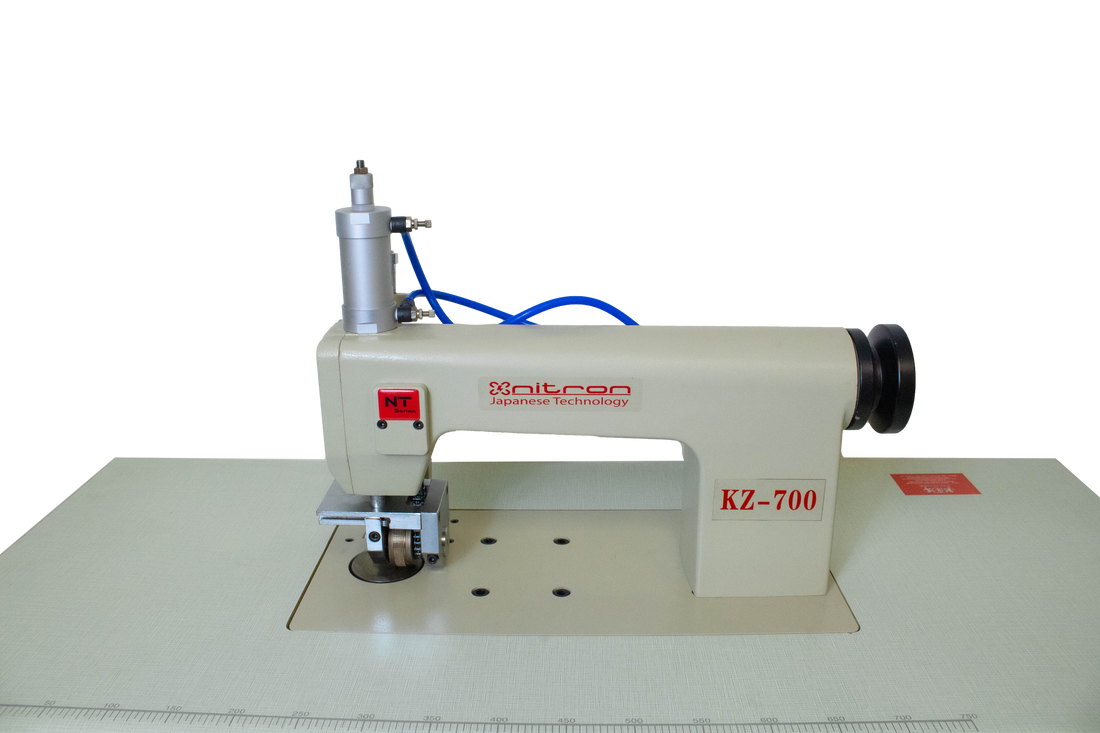

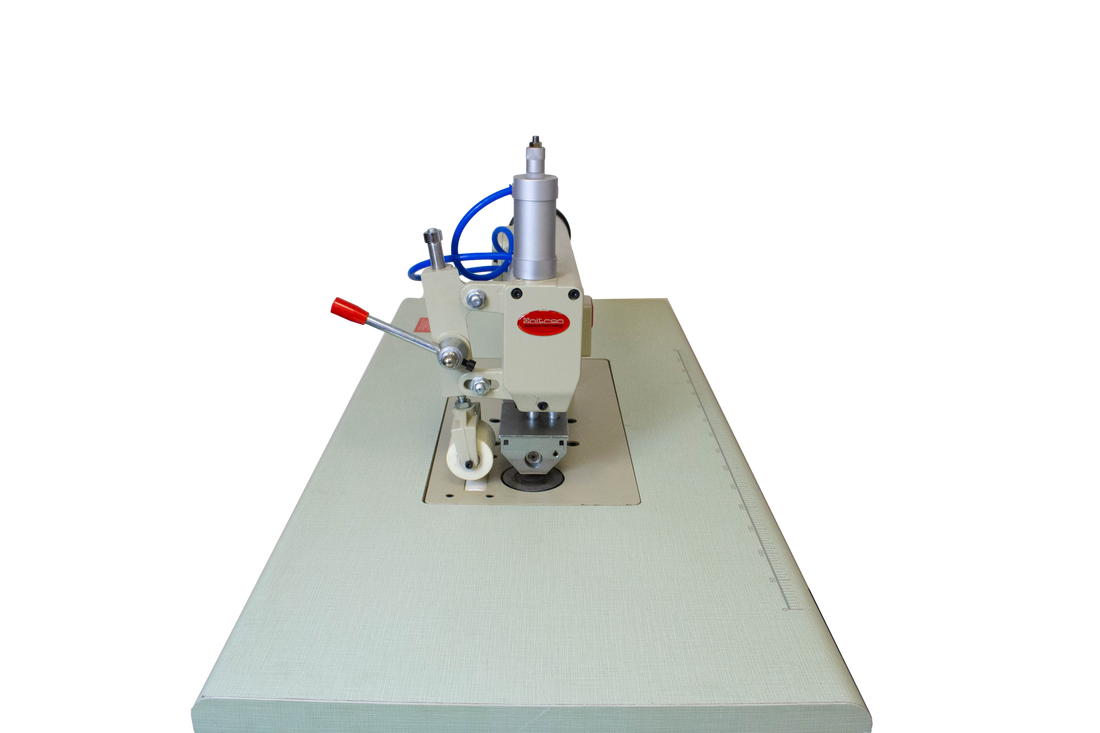

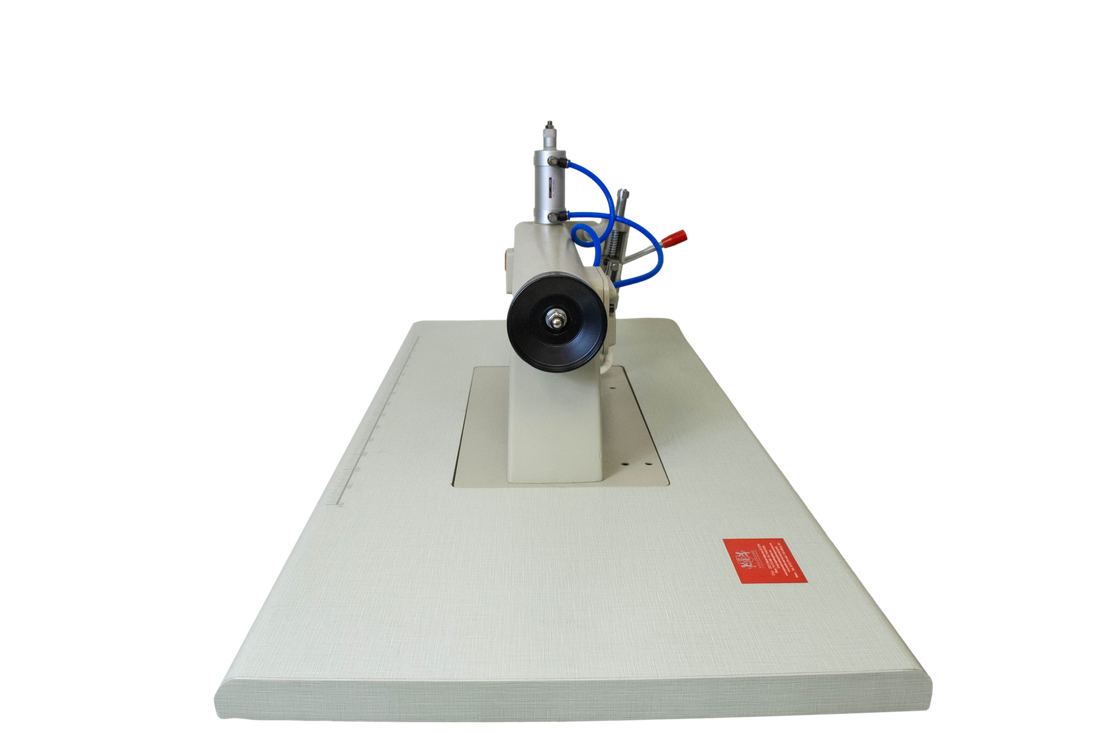

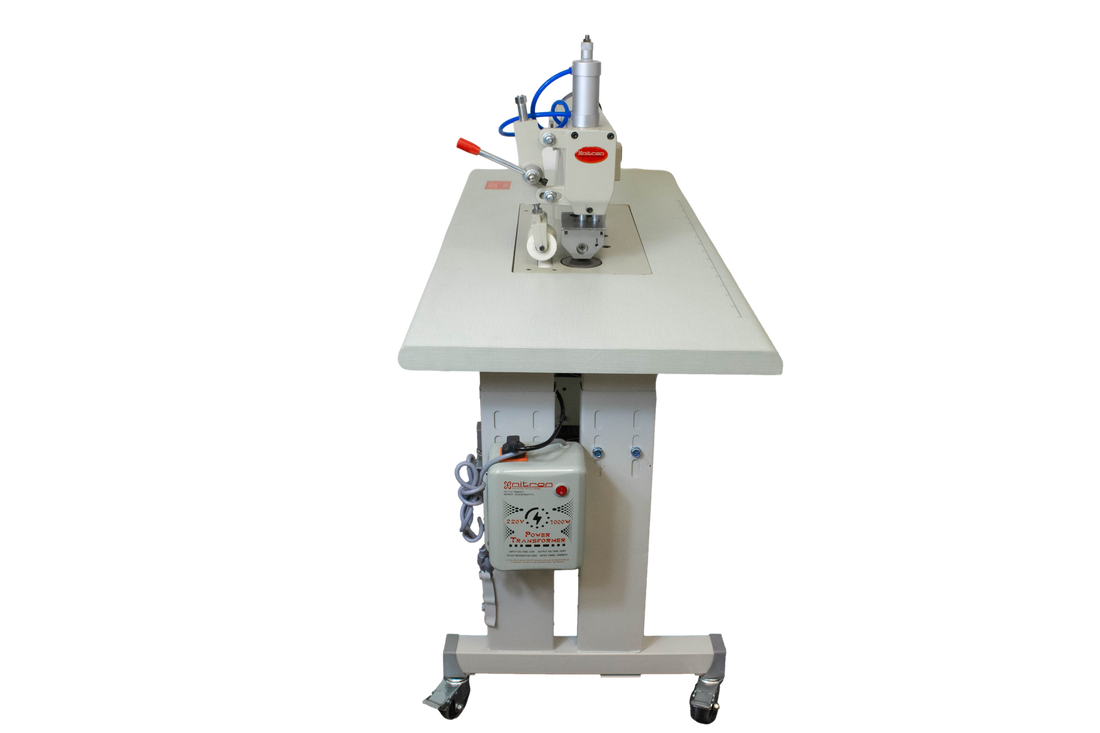

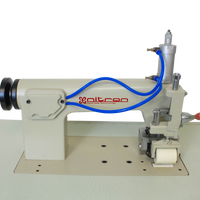

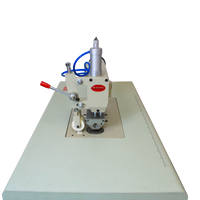

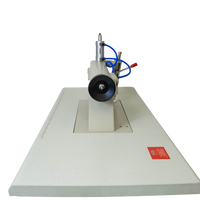

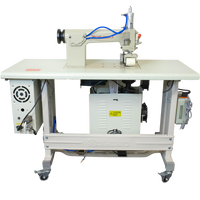

NT-700 ULTRASONIC SEWING MACHINE (60MM)

$3,550.00

- Description

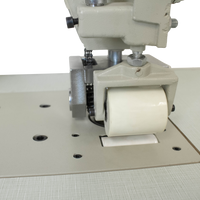

Suitable Materials: All kinds of artificial leather and fabric, non-woven fabric, spun-bonded cotton, thermoplastic film, chemical plastic piece, such as non-woven, PP non-woven, Polyester, Nylon, PU, PE, PE+ cloth, PE+ paper, PE+AL, etc.

Applications: Undergarments, ribbon, sportswear, packaging, phone cover, knitting products, tents, handbags, bed cover, tablecloth, handkerchief, window shades, shower shades, ribbons/laces, garments, disposable operating coat and hat, disposable mask, non-woven fabric cloth, umbrella edge lacing, holiday decorations and so on.

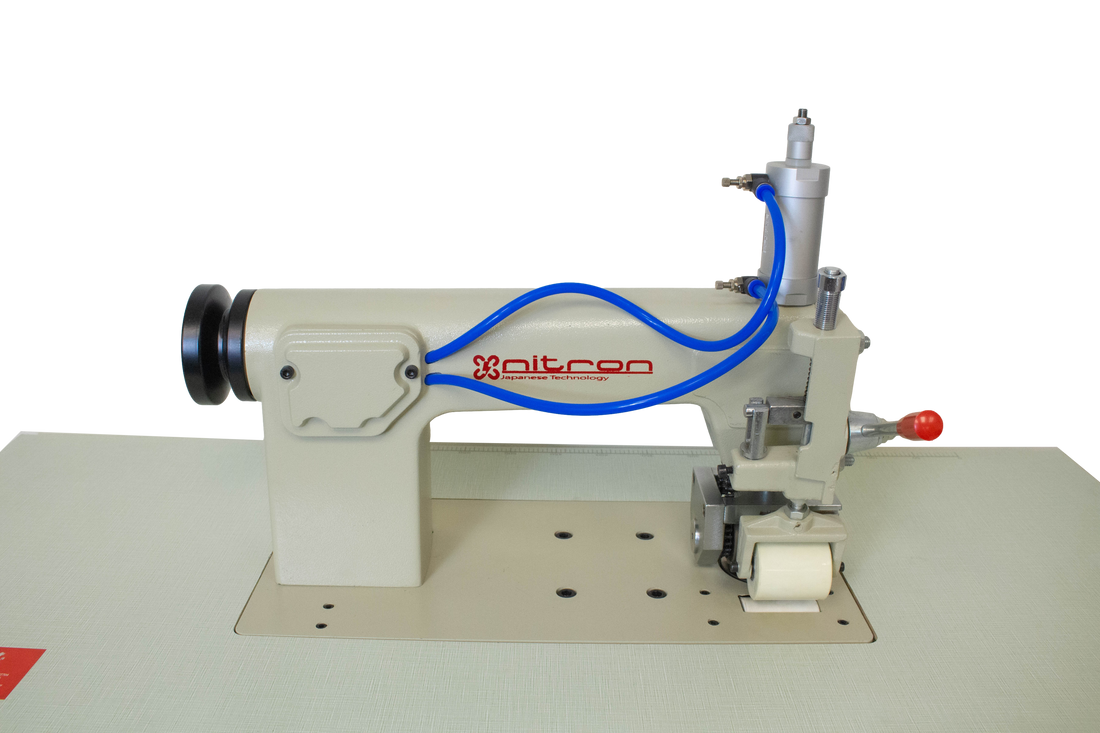

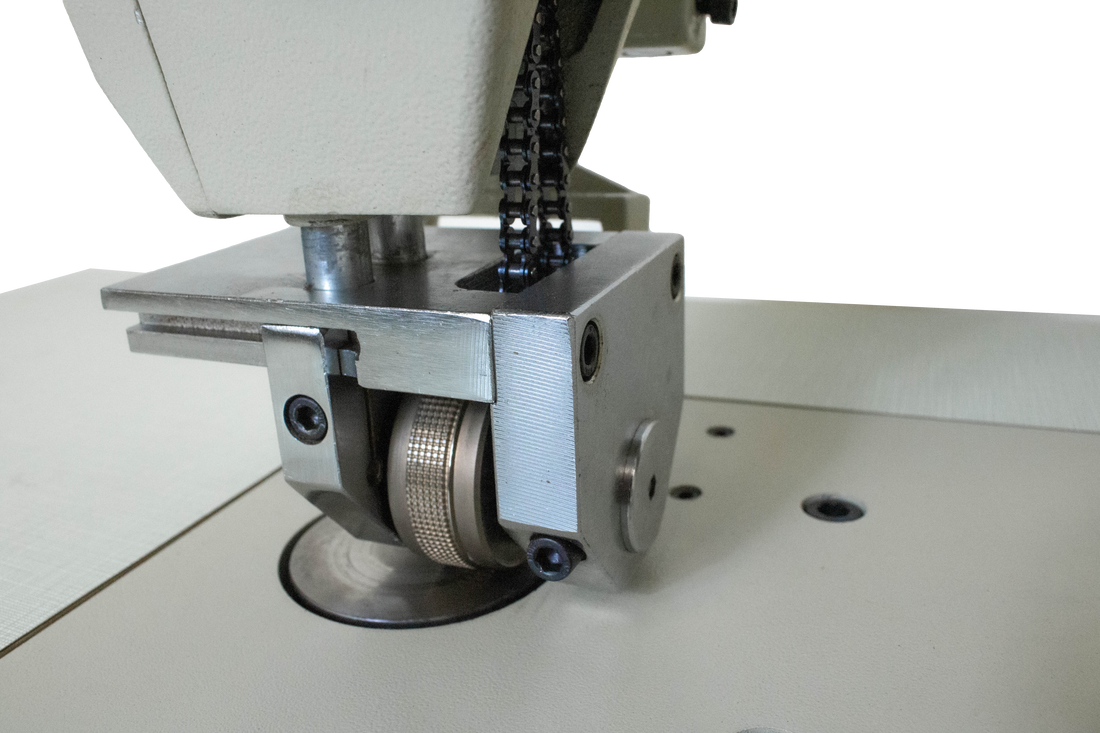

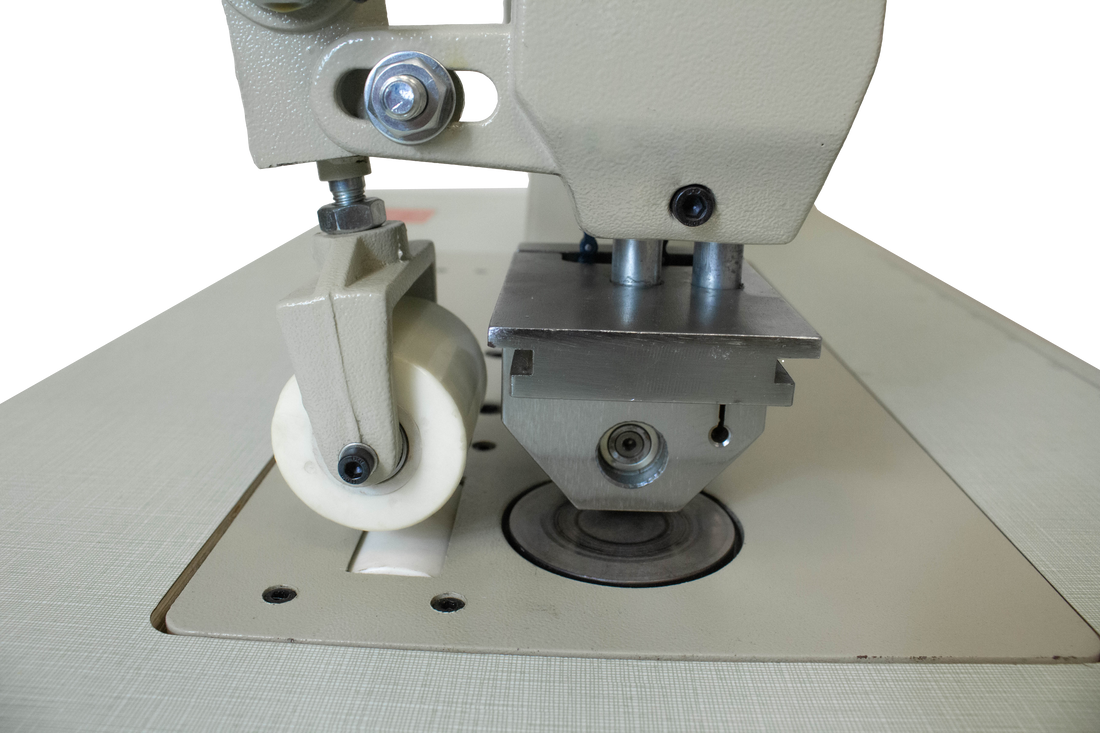

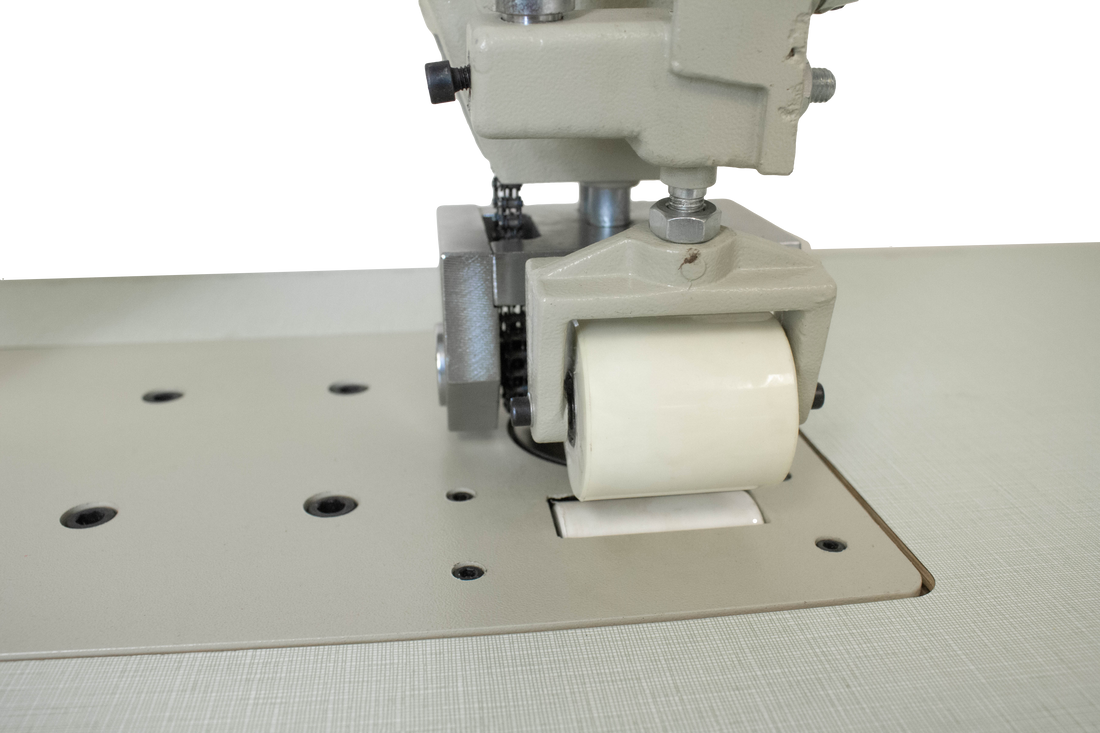

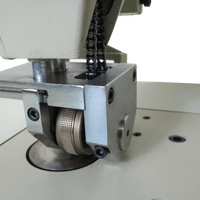

• Cutting: With a special design blade of roller to cut the edge in a continuously curved line as well as a straight line smoothly.

• Embossing/Color Coating: Transit the color through transit paper on the fabric for making products splendor and beauty.

• Welding: Continuous spot or zigzag shape welding efficiency to seal two or two more fabrics together without thread replacing the sewing needles rigidly.

• Hole Making: Different sizes of holes being cut out through ultrasonic vibration to form a specific pattern required.

• Forming: Usually two or three layers of fabric are cut and embossed to form a special shape product.

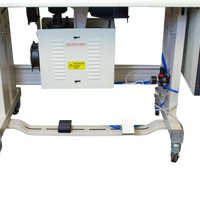

Specifications:

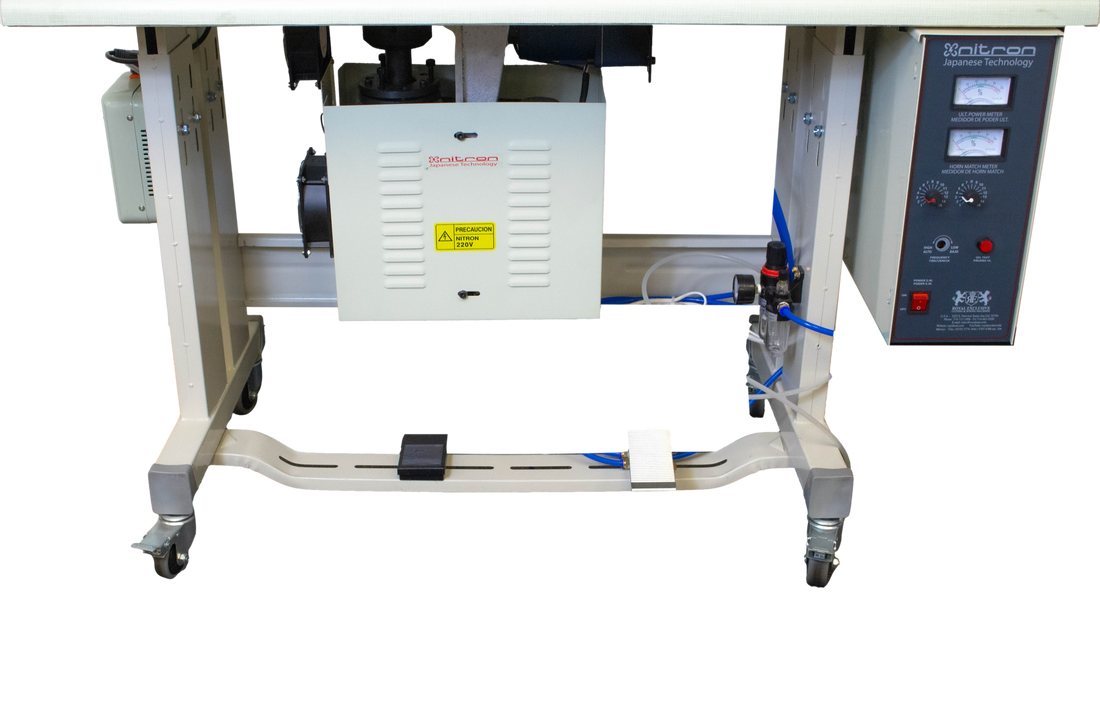

Source power 220V(or 110V available)

Ultrasonic power 2000W

Output frequency 20KHz

Working speed 0-20m/min

Roller size Width: 0-50mm;

Diameter: 50mm

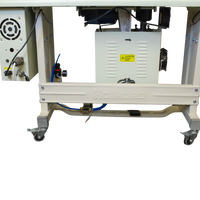

Dimension(L*W*H) 1200*600*1200mm

Net weight 90KG