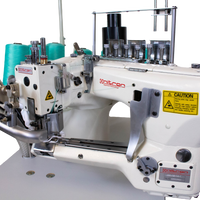

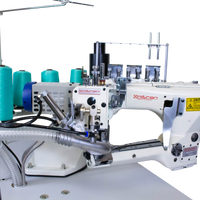

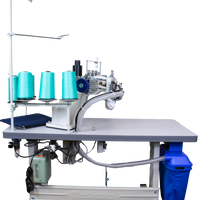

NT-6200-0 1ms-52d-7 FLAT LOCK INDUSTRIAL SEWING MACHINE (WITH CHAIN CUTTER)

- Description

General Description:

This system ensures smooth feeding of various fabrics: from single jersey to fleece, stretchable and uneven thickness portions. Besides, overlapping amount of upper/lower fabric is easily adjustable.

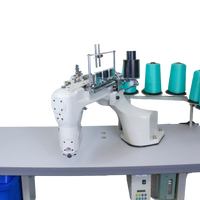

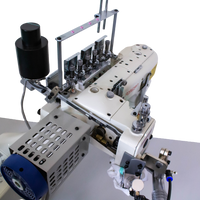

The small Cylinder-bed circumference at the needle dropping point is 148mm. The small cylinder bed enables small tubular operations. Also, a long cylinder of 200mm before the needle dropping point provides a wide operation space. Unique design for tangle-free and smooth supply of threads. Easily adjustable for differential ratio by outer lever. Thread tension can be adjusted individually for neat stitch formation.

The LJ-62000 is equipped with Direct Drive Computer which is designed for knitting sewing. This four needle and six needle machine can perform a high tension and very smooth side seam, the cylinder and working foot can easily go through the side seam and folding side. This model is equipped with sing cutter or double cutter it can finish different stitch on different materials. Suitable for light and medium garment sewing.

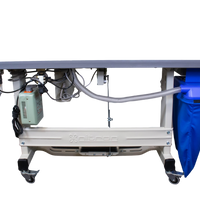

The automatic presser foot lifter for this device adopts an advanced feeding mechanism upgrading the efficiency. NOTE: (Air compression is required)

Specifications:

Needle: FLx118A4

Number of needles: 4

Number of threads: 6

Stitch length: 3-8mm

Needle gauge: 5.2mm

Edge trimmer: 30

Sewing speed (RPM): 4200

Presser foot height: 6mm

Power: 110V